Cast Models

Preparation for Casting

If the impression of originals is not possible, the reproduction takes place via a digital and non-contact 3D documentation. A positive for the cast is then produced from the 3D data. For models that do not show a high level of detail, a negative form can also be printed directly.

Depending on the surface appearance, application or budget, the following materials are used:

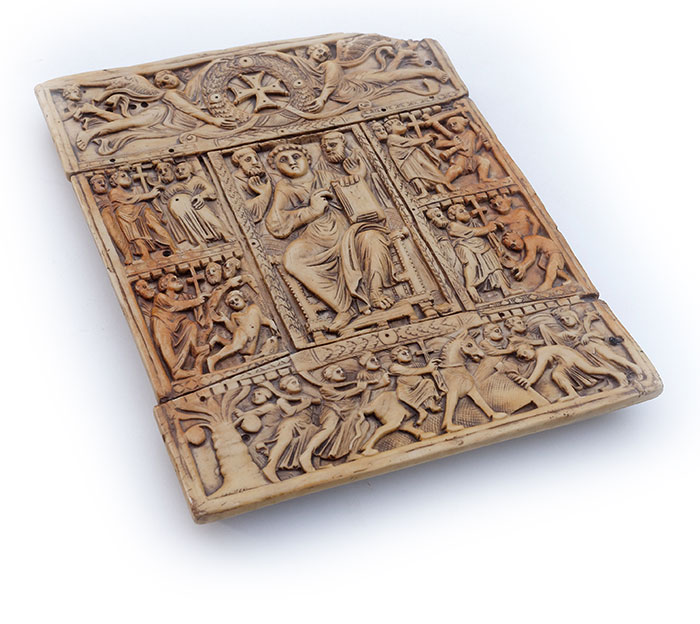

Synthetic resin is a cost-effective casting material which serves as a base. Different materials can also be added, such as stone powder, sand, ground bronze etc., as well as colour pigments. In doing so, not only is the colour appearance reproduced, but also the corresponding surface texture. Thus is it possible to create high-quality replicas of originals made from, for example, ivory, marble or bronze.

An additional patina or painting by an artist gives the replica a unique and “living” appearance.

We use bronze castings, for example, to produce models for the blind. Bronze is weatherproof and therefore suitable for outdoor use.

Bronze vs. Cold Bronze

The primary benefit of cold bronze is price reduction. In the production of cold bronze, the core is cast in pure synthetic resin and only ground bronze is added to the outer layer. This saves up to 60% in material costs compared to pure bronze. However, cold bronze is only partially weather-resistant. Therefore, it is often used for indoor exhibits or for small series in order to save costs. For permanent outdoor installation, cast bronze should be used.